Understanding the Different Types of Air Contaminants in Confined Spaces

"We may earn a commission for purchases made using our links. Please see our disclosure to learn more."

Confined spaces pose unique risks when it comes to air quality. Air contaminants in these spaces can jeopardize the health and safety of individuals working or entering such environments. It is crucial to have a comprehensive understanding of the various types of air contaminants that can be found in confined spaces to effectively mitigate risks and ensure a safe working environment.

In this blog post, we will explore the different types of air contaminants commonly encountered in confined spaces. From hazardous gases, such as carbon monoxide and hydrogen sulfide, to particulate matter like dust and fibers, we will delve into each category, highlighting their potential sources and associated health hazards. By familiarizing ourselves with these contaminants, we can better comprehend the importance of proper ventilation, personal protective equipment (PPE), and regular monitoring to maintain air quality within confined spaces.

Join us as we unlock the knowledge necessary to identify, assess, and address air contaminants in confined spaces. By doing so, we can prioritize the well-being of workers and minimize the potential for accidents and illnesses related to poor air quality. Stay tuned for our upcoming posts, where we will delve deeper into strategies for preventing and controlling air contaminants in confined spaces.

Understanding the Different Types of Air Contaminants in Confined Spaces

What are Confined Spaces?

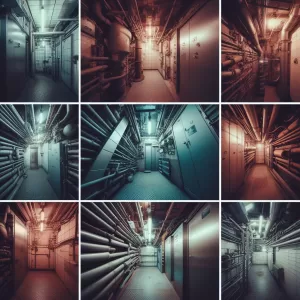

A confined space refers to any enclosed or partially enclosed area that may have limited means of entry or exit, and is not designed for continuous occupancy. These spaces are usually not meant for regular human habitation, but rather for specific purposes such as storage, maintenance, or repair work. Confined spaces pose unique risks and hazards, particularly when it comes to air quality and the presence of harmful contaminants.

Definition of Confined Spaces

Confined spaces can be defined as areas that meet the following criteria:

- Limited means of entry or exit: Confined spaces typically have restricted access points, which can make it challenging to enter or exit quickly in the event of an emergency. Examples include tanks, silos, vaults, and crawl spaces.

- Not designed for continuous occupancy: Unlike regular workspaces or living areas, confined spaces are not intended for extended human presence. They are usually cramped, poorly ventilated, and lack basic amenities.

- Potential hazards: Confined spaces are more prone to certain hazards, such as poor air quality, toxic substances, low oxygen levels, or the presence of flammable gases. These factors can increase the risk of accidents, injuries, and even fatalities.

Examples of Confined Spaces

Confined spaces can vary greatly in nature, but some common examples include:

- Tanks and Vessels: Large containers used for storage or transport of liquids or gases, such as underground storage tanks, fuel tanks, or chemical processing vessels.

- Silos and Hoppers: Enclosed structures used for storing bulk materials like grain, cement, or coal. These spaces often have limited access and can present risks of suffocation or engulfment.

- Tunnels and Pipelines: Underground passages or channels used for transportation of utilities, such as sewage systems or gas pipelines. These spaces may lack proper ventilation and pose risks of exposure to hazardous gases.

- Confined Rooms: Small, enclosed rooms or chambers, such as boiler rooms, electrical vaults, or control rooms. These spaces may contain equipment or machinery that emits potentially harmful fumes or gases.

- Sewers and Crawl Spaces: Underground passages or narrow crawl spaces beneath buildings or infrastructure, often containing hazardous substances, gases, or the risk of entrapment.

Understanding the concept of confined spaces and their specific examples is crucial in comprehending the unique risks associated with working in such environments. By recognizing these risks, employers and workers can take appropriate measures to ensure safety and mitigate potential hazards.

Please note, for more detailed information on confined spaces and their associated risks, you can refer to the Occupational Safety and Health Administration (OSHA) website or the National Institute for Occupational Safety and Health (NIOSH) website.

Importance of Air Quality in Confined Spaces

Working in confined spaces presents unique challenges and hazards, making it crucial to prioritize air quality. In this section, we will explore the health risks associated with poor air quality and the legal regulations and standards that govern air quality in confined spaces.

Health Risks Associated with Poor Air Quality

Poor air quality in confined spaces can have severe health consequences for workers. The lack of natural ventilation and limited means of entry and exit contribute to the accumulation of contaminants, posing various health risks. Some of the potential health hazards include:

- Reduced Oxygen Levels: Inadequate oxygen levels can lead to dizziness, fatigue, impaired judgment, loss of consciousness, and even asphyxiation. It is important to monitor oxygen levels regularly in confined spaces to ensure the safety of workers.

- Toxic Gases and Chemical Exposure: Confined spaces may contain toxic gases, vapors, or chemicals, which can be released during certain work operations. Inhalation of these substances can result in respiratory problems, organ damage, and even death.

- Airborne Particles and Dust: Activities such as welding, cutting, or grinding can produce airborne particles and dust, leading to respiratory issues, eye irritation, and other health complications.

- Stratification and Varying Air Compositions: Confined spaces often experience stratification, where different air compositions layer from floor to ceiling. This can result in uneven distribution of contaminants, making it essential to monitor air quality across different elevations.

Given these health risks, it is crucial to prioritize and maintain good air quality in confined spaces to safeguard the well-being of workers.

Legal Regulations and Standards for Air Quality in Confined Spaces

To ensure the safety of workers in confined spaces, various legal regulations and standards have been established. These regulations aim to provide guidelines for employers and workers to follow in order to maintain adequate air quality. Some important regulations and standards include:

- Occupational Safety and Health Administration (OSHA) Standards: OSHA has set forth specific standards for confined spaces, including regulations for air quality. These standards define the responsibilities of employers, such as identifying confined spaces, conducting air monitoring, implementing ventilation systems, and providing proper training for workers.

- Permit-Required Confined Spaces (PRCS): Certain confined spaces are classified as permit-required, indicating that they have additional hazards and stricter air quality requirements. PRCS standards outline the procedures and precautions necessary for entry into these spaces, including thorough air testing and the use of appropriate personal protective equipment.

Complying with these regulations is crucial to ensure a safe and healthy work environment for individuals working in confined spaces. It is important for employers and workers to stay updated on the relevant regulations and implement necessary measures to maintain optimal air quality.

Remember, prioritizing air quality in confined spaces is essential for the well-being of workers and the overall success of any project. By understanding the health risks associated with poor air quality and adhering to legal regulations, we can create safer work environments and protect the health of those who work in confined spaces.

Understanding the Different Types of Air Contaminants in Confined Spaces

Common Types of Air Contaminants in Confined Spaces

Confined spaces, such as tunnels, storage tanks, and crawl spaces, can pose serious risks due to the presence of various air contaminants. It is crucial to understand the different types of air contaminants that can be found in these confined spaces to ensure the safety and well-being of workers. In this section, we will explore three common types of air contaminants: dust and particulate matter, chemical vapors and gases, and biological contaminants.

Dust and Particulate Matter

Dust and particulate matter refers to solid particles suspended in the air, typically arising from processes such as grinding, cutting, or pulverizing materials. These particles can vary in size, ranging from visible dust to microscopic particles that are not perceptible to the naked eye. When inhaled, dust and particulate matter can irritate the respiratory system, cause allergies, or even lead to serious lung diseases over time.

To effectively mitigate the risks associated with dust and particulate matter, it is essential to implement proper engineering controls, such as dust collectors and ventilation systems. Personal protective equipment (PPE), including respirators and face masks, should also be worn by workers exposed to these contaminants. Regular cleaning and maintenance of equipment and work areas can further help in minimizing the accumulation of dust and particulate matter.

Chemical Vapors and Gases

Chemical vapors and gases are another common type of air contaminant found in confined spaces. They can originate from various sources, including paints, solvents, fuels, and industrial processes. Inhalation of these vapors and gases can have immediate health effects, such as dizziness, nausea, or respiratory irritation, and in severe cases, they can even lead to unconsciousness or death.

To ensure the safety of workers, it is crucial to conduct a thorough assessment of the confined space to identify the presence of any potential chemical hazards. Adequate ventilation systems, including local exhaust ventilation, should be implemented to remove or dilute any released vapors or gases. It is also important to provide workers with appropriate respiratory protection equipment and ensure they receive training on the proper handling and use of chemicals.

Biological Contaminants

Biological contaminants refer to living organisms or their byproducts that can be present in the air within confined spaces. These contaminants can include bacteria, fungi, molds, viruses, and their associated toxins. Inhaling or coming into contact with these biological contaminants can result in allergic reactions, respiratory infections, or other health issues.

Preventing the presence and growth of biological contaminants requires maintaining proper sanitation and cleanliness within confined spaces. Regular cleaning, disinfection, and moisture control can help minimize the risk of mold and bacterial growth. Additionally, implementing appropriate personal hygiene practices, such as handwashing and using protective gloves, can further reduce the potential for exposure to biological contaminants.

When working in confined spaces, it is essential to be aware of the different types of air contaminants that can be present. By understanding the risks associated with dust and particulate matter, chemical vapors and gases, and biological contaminants, precautions can be taken to minimize exposure and ensure the safety of workers. Compliance with relevant safety regulations, regular monitoring, and proper training are key to maintaining a healthy and hazard-free work environment.

Related resources:

- Occupational Safety and Health Administration (OSHA) provides guidelines and regulations for working in confined spaces.

- National Institute for Occupational Safety and Health (NIOSH) offers research and recommendations on workplace safety and health.

Understanding the Different Types of Air Contaminants in Confined Spaces

Sources of Air Contaminants in Confined Spaces

In confined spaces, there are various sources of air contaminants that can pose risks to individuals working within these environments. It is crucial to identify these sources to effectively manage and mitigate potential health hazards. The following are the primary sources of air contaminants in confined spaces:

Industrial Processes and Emissions

Industrial processes often generate air contaminants that can accumulate in confined spaces. These contaminants may include gases, fumes, dust, and vapors. For instance, chemical manufacturing facilities release toxic gases and volatile organic compounds (VOCs) during production processes. Similarly, petrochemical complexes emit harmful emissions, such as sulfur dioxide and nitrogen oxides.

The release of these pollutants can occur due to improper ventilation, equipment malfunction, or faulty industrial processes. Understanding the potential sources of air contaminants in industrial settings is crucial for implementing effective control measures to minimize exposure risks.

Equipment and Machinery

Equipment and machinery used in confined spaces can also contribute to air contamination. Engines, generators, and other combustion sources produce exhaust fumes that contain dangerous gases, such as carbon monoxide and nitrogen dioxide. Additionally, equipment that generates dust particles or releases aerosols can introduce particulate matter into the air.

Maintenance activities involving machinery can further release contaminants, especially when cleaning or repairing equipment without proper precautions. It is essential to ensure regular maintenance, proper ventilation, and the use of appropriate exhaust systems to minimize the emissions from equipment and machinery within confined spaces.

Human Activities

Human activities within confined spaces can introduce air contaminants that pose health risks. This can include activities like smoking, spraying aerosols, or using chemicals without adequate ventilation. Additionally, improper waste disposal or spills of hazardous substances can lead to the release of harmful gases or fumes.

Workers themselves can also contribute to air contamination through shedding of skin cells, hair, or droplet nuclei, especially in crowded confined spaces. Improper personal hygiene practices, such as not washing hands properly, can further worsen the situation. Educating workers about proper behavior and providing them with necessary personal protective equipment (PPE) can help minimize the impact of human activities on air quality.

Understanding the sources of air contaminants in confined spaces is vital for implementing effective control measures. By addressing industrial processes and emissions, equipment and machinery, and human activities, it is possible to reduce the levels of air contaminants and create safer working environments for individuals in confined spaces.

Effects of Air Contaminants on Human Health

Air contaminants in confined spaces can have detrimental effects on human health. These contaminants can lead to various respiratory issues, allergic reactions, and even the development of chronic health conditions. Understanding these effects is crucial for ensuring the safety and well-being of individuals working in or exposed to confined spaces.

Respiratory Issues

One of the primary health concerns associated with air contaminants in confined spaces is the development of respiratory issues. Inhalation of pollutants such as dust, gases, or chemicals can irritate the respiratory system, leading to symptoms such as coughing, wheezing, shortness of breath, and chest tightness.

Prolonged exposure to these contaminants can result in more severe conditions, including bronchitis, asthma, and in extreme cases, respiratory failure. It is essential to recognize the signs of respiratory distress and seek medical attention promptly if any symptoms arise.

Allergic Reactions

In addition to respiratory issues, air contaminants in confined spaces can also trigger allergic reactions in susceptible individuals. These reactions can manifest as itchy or watery eyes, sneezing, nasal congestion, and skin rashes.

Some people may have existing allergies that are aggravated by certain pollutants present in confined spaces. It is crucial to identify potential allergens and take appropriate measures to prevent exposure, such as wearing personal protective equipment (PPE) or implementing proper ventilation systems. Seeking medical advice for allergy management is also recommended.

Chronic Health Conditions

Long-term exposure to air contaminants in confined spaces can lead to the development of chronic health conditions. Certain chemicals and toxic substances found in confined spaces have been linked to serious illnesses, including cancer, neurological disorders, and organ damage.

It is crucial to understand the specific substances present in a confined space and their potential health risks. Regular monitoring of air quality and implementing effective control measures can significantly reduce the likelihood of chronic health conditions developing as a result of exposure.

In conclusion, air contaminants in confined spaces pose significant risks to human health. Respiratory issues, allergic reactions, and chronic health conditions are among the various detrimental effects that individuals may experience when exposed to these pollutants. Recognizing these risks and implementing appropriate preventive measures are essential for safeguarding the well-being of those working in confined spaces.

Remember to consult reputable sources such as the Occupational Safety and Health Administration (OSHA) or the National Institute for Occupational Safety and Health (NIOSH) for more detailed information on air contaminants and their effects on human health.

Monitoring and Detection of Air Contaminants

Air quality is a crucial factor to consider, especially in confined spaces where the accumulation of air contaminants can pose significant risks to human health and safety. Monitoring and detecting air contaminants is essential to ensure a safe working environment. This section will explore various methods and equipment used for monitoring and detection in confined spaces.

Air Sampling Techniques

Air sampling techniques are used to collect samples of air from confined spaces for analysis to determine the presence and concentration of air contaminants. There are different methods of air sampling, including grab sampling and integrated sampling.

- Grab Sampling: Grab sampling involves capturing a sample of air at a specific moment in time. This method is suitable for identifying short-term variations in air quality. A sample pump is used to draw a predetermined volume of air into a sampling container, which is then sent to a laboratory for analysis.

- Integrated Sampling: Integrated sampling is performed over an extended period to provide an average concentration of air contaminants over time. This method is useful for assessing long-term exposure risks. A common integrated sampling technique is passive sampling, which uses sorbent materials to collect air contaminants continuously.

Gas Detectors and Monitoring Systems

Gas detectors and monitoring systems are essential tools for detecting and measuring the concentration of gases and other air contaminants in confined spaces. These devices help ensure the timely detection of hazardous substances, allowing for prompt action to protect workers.

- Portable Gas Detectors: Portable gas detectors are handheld devices that provide real-time monitoring of gas levels. They are compact and lightweight, allowing workers to carry them easily when moving around confined spaces. These detectors can detect specific gases or provide multi-gas monitoring capabilities.

- Fixed Gas Monitoring Systems: Fixed gas monitoring systems are permanently installed in confined spaces to continuously monitor air quality. They consist of sensors strategically placed throughout the area to detect the presence of specific gases. These systems often come with alarms or warning devices to alert workers in case of high gas concentrations.

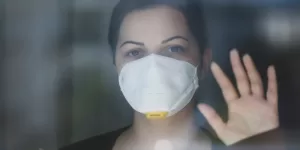

Personal Protective Equipment (PPE)

While monitoring and detection systems are crucial, personal protective equipment (PPE) is another line of defense to protect workers from air contaminants in confined spaces. PPE acts as a physical barrier between the worker and the hazardous substances present in the air.

- Respiratory Protection: Respiratory protection, such as respirators and masks, is essential for preventing inhalation of harmful airborne contaminants. Different types of respirators are available, ranging from disposable masks to self-contained breathing apparatus (SCBA) for higher levels of respiratory protection.

- Protective Clothing: Protective clothing, including coveralls, gloves, and boots, can shield workers from direct contact with hazardous substances present in the air or on surfaces. The clothing should be made from appropriate materials and designed to provide adequate protection against specific chemicals or contaminants.

- Eye and Face Protection: Eye and face protection, such as safety goggles and face shields, are necessary to prevent airborne particles, gases, or liquids from reaching the eyes and causing injury. These protective measures are particularly crucial when working in environments where there is a risk of splashing or spraying of hazardous substances.

In conclusion, monitoring and detection of air contaminants in confined spaces is critical for ensuring the safety and well-being of workers. By using air sampling techniques, gas detectors, monitoring systems, and personal protective equipment, companies can effectively manage and mitigate risks associated with air contamination. Regular monitoring and the use of appropriate protective measures are essential to maintain a healthy and safe working environment.

In conclusion, monitoring and detection of air contaminants in confined spaces is critical for ensuring the safety and well-being of workers. By using air sampling techniques, gas detectors, monitoring systems, and personal protective equipment, companies can effectively manage and mitigate risks associated with air contamination. Regular monitoring and the use of appropriate protective measures are essential to maintain a healthy and safe working environment.

Remember to consult relevant regulations and guidelines to ensure compliance with safety standards when monitoring and detecting air contaminants in confined spaces. Understanding the Different Types of Air Contaminants in Confined Spaces

Prevention and Control Measures for Air Contaminants

Air contaminants can pose serious health risks in confined spaces. However, implementing effective prevention and control measures can help mitigate these risks and create a safer working environment. This section will explore three key methods for preventing and controlling air contaminants: ventilation systems, engineering controls, and personal hygiene practices.

Ventilation Systems

Ventilation systems play a crucial role in maintaining good air quality in confined spaces. They help remove airborne contaminants, decrease humidity levels, and provide fresh air circulation. One common type of ventilation system is the general mechanical ventilation system, which uses fans and ducts to exhaust and supply air. This system helps dilute and remove contaminants, ensuring a healthier breathing environment for workers.

Another type of ventilation system is the local exhaust ventilation (LEV) system. This system is specifically designed to capture and remove contaminants at their source, such as fumes or dust generated by certain processes. LEV systems use hoods, ductwork, and fans to effectively control and remove airborne pollutants, preventing them from spreading throughout the confined space.

Implementing appropriate ventilation systems not only helps protect workers from exposure to air contaminants but also ensures compliance with regulatory standards. To learn more about ventilation systems, you can visit [insert relevant link to external website].

Engineering Controls

In addition to ventilation systems, engineering controls provide another layer of protection against air contaminants in confined spaces. These controls involve modifying or redesigning the work environment or equipment to prevent or minimize exposure to hazards.

One example of an engineering control is the use of enclosures or barriers. These physical barriers can isolate and contain the source of contaminants, preventing them from spreading into the surrounding area. By confining the contaminants to a specific space, workers are shielded from direct exposure.

Another engineering control measure is substitution. This involves replacing hazardous substances or processes with safer alternatives. For instance, if a certain chemical used in a confined space poses a significant health risk, finding a less toxic substitute can minimize the potential harm to workers.

By implementing effective engineering controls, companies can proactively reduce the presence of air contaminants and create a safer workspace for their employees. For more information on engineering controls, consider visiting [insert relevant link to external website].

Personal Hygiene Practices

While ventilation systems and engineering controls play important roles in preventing and controlling air contaminants, personal hygiene practices are equally essential. These practices help ensure that workers are not inadvertently introducing contaminants into the confined space or exposing themselves to unnecessary health risks.

Some key personal hygiene practices include:

- Wearing appropriate personal protective equipment (PPE), such as respirators, gloves, or coveralls, to minimize direct contact with air contaminants.

- Regularly washing hands with soap and water before and after working in a confined space.

- Avoiding eating, drinking, or smoking in confined spaces to prevent ingestion or inhalation of contaminants.

- Following proper decontamination procedures when leaving the confined space to prevent cross-contamination.

By promoting and enforcing these personal hygiene practices, companies can significantly reduce the potential for air contamination and protect the health and safety of their workers.

In conclusion, prevention and control measures for air contaminants in confined spaces involve the use of ventilation systems, engineering controls, and personal hygiene practices. By implementing these measures, companies can create a healthier and safer working environment, minimizing the risks associated with air contaminants.

Remember to always consult relevant safety guidelines and regulations to ensure compliance and best practices when it comes to preventing and controlling air contaminants in confined spaces.

Training and Education for Confined Space Workers

Proper training and education are essential for workers who are required to work in confined spaces. Without adequate knowledge and understanding of the potential hazards and safety procedures, workers may be at risk of accidents, injuries, or even fatalities. In this section, we will explore the importance of proper training for confined space workers and discuss the topics that should be covered in confined space training programs.

Importance of Proper Training

Training plays a crucial role in ensuring the safety of confined space workers. It provides workers with the necessary knowledge and skills to identify potential hazards, assess risks, and implement appropriate safety measures. Proper training can help workers understand the specific requirements outlined in the OSHA Confined Space standard 29 CFR 1910.146 and equip them with the tools to comply with these regulations.

Without adequate training, workers may not be aware of the potential dangers associated with confined spaces and may not know how to protect themselves and their colleagues. This lack of knowledge can lead to accidents, injuries, or even fatalities, which can have severe consequences not only for the individuals involved but also for the reputation and financial stability of the company.

By investing in comprehensive training programs, employers can ensure that their workers are fully prepared to enter and work in confined spaces safely. This not only reduces the risk of accidents but also promotes a culture of safety within the workplace, where workers are empowered to prioritize their own well-being and that of their colleagues.

Topics to Cover in Confined Space Training Programs

Confined space training programs should cover a range of topics to ensure that workers have a comprehensive understanding of the hazards and procedures associated with working in confined spaces. Here are some key topics that should be included:

- Definition of Confined Spaces: It is important to establish a clear understanding of what constitutes a confined space. This includes identifying various types of confined spaces, such as underground vaults, tanks, storage bins, manholes, pits, silos, process vessels, and pipelines.

- OSHA Regulations: Provide an overview of the OSHA Confined Space standard 29 CFR 1910.146 to familiarize workers with the requirements they need to adhere to while working in confined spaces. This can include topics such as permit-required confined spaces, hazardous atmosphere, engulfment hazards, and other safety or health hazards.

- Identifying Hazards: Teach workers how to identify potential hazards within confined spaces, such as hazardous atmospheres, engulfment risks, physical hazards, and other safety or health hazards. Emphasize the importance of conducting thorough hazard assessments before entering a confined space.

- Atmospheric Monitoring: Explain the significance of continuous atmospheric monitoring to detect and monitor potential hazards, including oxygen levels, flammable gases, toxic substances, and other airborne contaminants. Provide guidance on how to use monitoring equipment properly and interpret the readings.

- Personal Protective Equipment (PPE): Educate workers on the appropriate selection, use, and maintenance of personal protective equipment for confined space entry. This includes respiratory protection, fall protection, protective clothing, and other relevant safety gear.

- Entry and Exit Procedures: Outline the proper procedures for entering and exiting confined spaces, including the use of permits, communication systems, lockout/tagout procedures, and emergency response protocols. Emphasize the importance of teamwork, clear communication, and following established procedures.

- Emergency Response: Prepare workers for emergency situations that may arise within confined spaces. This includes training on rescue techniques, first aid procedures, evacuation procedures, and the importance of having a well-defined emergency response plan.

By covering these topics in confined space training programs, workers will be equipped with the necessary knowledge and skills to navigate and safely work in confined spaces. Employers should ensure that training is regularly refreshed and updated to reflect any changes in regulations or best practices.

Remember, proper training and education are essential for the safety of confined space workers. By investing in comprehensive training programs and covering the necessary topics, employers can minimize the risk of accidents and create a safer working environment for their employees.

Note: The information provided in this section is for educational purposes only and does not substitute for official training or legal advice. Always refer to OSHA regulations and consult with experts for specific guidance in your workplace.

Conclusion

In conclusion, it is crucial to have a clear understanding of the different types of air contaminants present in confined spaces. By being aware of these contaminants, we can take appropriate measures to protect ourselves and others from potential health hazards. Whether it is gases, vapors, or particulate matter, each type of contaminant requires specific control measures to ensure a safe working environment. Regular monitoring, adequate ventilation, and the use of personal protective equipment are essential in mitigating the risks associated with air contaminants. Remember, knowledge is power when it comes to protecting ourselves from harmful substances in confined spaces. Stay informed, stay safe.